A Parts/Materials Selection and Application Program is an approach to controlling those items that are used in your product/system design. It establishes the requirements and defines the controls that make them acceptable for use for a given design, application environment and expected life. It considers related issues such as the risks associated with new technologies, part/material obsolescence and Diminishing Manufacturing Sources (DMS).

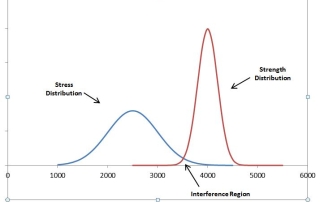

Interference Stress/Strength Analysis

In simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More

Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your Design

Engineers are often faced with the problem of optimizing a process that includes a number of input variables. It could be an analysis of a manufacturing process, or even an analysis of a business process. They’re often challenged to find ways to reduce Read More

Which Design is More Reliable? Weibull Provides Answers!

Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More