Much of the Center’s expertise in the RMQ disciplines is captured in a variety of publications on reliability-related topics. For those that prefer to learn the basics from these educational texts, or to have a reference guide for later use, the RMQSI Knowledge Center offers a number of resources. These guides vary in subject and depth of discussion, and are intended to address different readers’ level of expertise on a particular subject matter. Two of the most popular introductory-level guides are described below.

Reliability Ques

Reliability Queues are tech briefs describing commonly used tools, techniques, and overall approaches to ensuring the reliability of a developed product or system. This free resource addresses a number of topic-specific, real-world situations that engineers experience. The collection is routinely updated to keep the community abreast of new developments in the field.

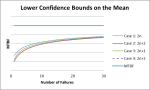

Confidence Bounds on the Mean Time Between Failure (MTBF) for a Time-Truncated TestThere is a long standing discussion on how best to calculate the lower and upper confidence bounds on the Mean Time Between Failure (MTBF) for a time-truncated test (Type I Censoring) assuming that the times between failure are exponentially distributed (constant failure rate).

Confidence Bounds on the Mean Time Between Failure (MTBF) for a Time-Truncated TestThere is a long standing discussion on how best to calculate the lower and upper confidence bounds on the Mean Time Between Failure (MTBF) for a time-truncated test (Type I Censoring) assuming that the times between failure are exponentially distributed (constant failure rate). Maintenance Planning with Wearout Failure ModesThis Reliability Que will discuss how Weibull analysis qualitative results showing a wearout failure mode can be utilized to quantitatively drive the decision making process in Reliability Centered Maintenance (RCM) programs.

Maintenance Planning with Wearout Failure ModesThis Reliability Que will discuss how Weibull analysis qualitative results showing a wearout failure mode can be utilized to quantitatively drive the decision making process in Reliability Centered Maintenance (RCM) programs. Maintenance Planning with a Constant Failure RateThis Reliability Que will discuss an example of how Weibull analysis qualitative results showing a constant failure rate affect the maintenance planning process. The qualitative results can be utilized to quantitatively drive the decision-making process in Reliability Centered Maintenance (RCM) programs.

Maintenance Planning with a Constant Failure RateThis Reliability Que will discuss an example of how Weibull analysis qualitative results showing a constant failure rate affect the maintenance planning process. The qualitative results can be utilized to quantitatively drive the decision-making process in Reliability Centered Maintenance (RCM) programs.

Browse the full list of Reliability Queues.

RELease Book Series

The “RELease” Book Series is intended for the beginner to the reliability, maintainability and quality (RMQ) disciplines. Each book in the series introduces the reader to a basic reliability concept or technique, describing its purpose (e.g., the goal of a test or analysis), the situations in which it is performed, and most importantly, how it may be performed. The series’ name is intended to reflect the goal of simplifying the various practices and techniques to enable the reader to perform reliability with ease (Rel-ease). A few of the most popular RElease Guides are presented below.

Accelerated TestingThe length of time required to perform certain reliability tests can be prohibitive. Tests performed to improve a product through the elimination of design defects or to estimate its design life are dependent upon the rate at which failures are precipitated and corrected. Through the application of increased electrical, mechanical and thermal stresses, cycling frequency or operational duty cycles, damage can be accumulated more quickly. This damage accumulation then leads to failure precipitation. If the magnitude of the increase in stress is known and controlled, various models can be used to quantify the acceleration.

Accelerated TestingThe length of time required to perform certain reliability tests can be prohibitive. Tests performed to improve a product through the elimination of design defects or to estimate its design life are dependent upon the rate at which failures are precipitated and corrected. Through the application of increased electrical, mechanical and thermal stresses, cycling frequency or operational duty cycles, damage can be accumulated more quickly. This damage accumulation then leads to failure precipitation. If the magnitude of the increase in stress is known and controlled, various models can be used to quantify the acceleration. Reliability PredictionTraditionally, reliability predictions have been predominantly based on the results of a formal test program. While testing is a more than acceptable means of estimating a system’s performance in the field, it typically cannot be performed until a prototype can be constructed from a fairly mature design. Unfortunately, a significant amount of time and money have already been expended at this stage of development, and any changes to the design (to address a reliability shortfall) are typically quite costly.

Reliability PredictionTraditionally, reliability predictions have been predominantly based on the results of a formal test program. While testing is a more than acceptable means of estimating a system’s performance in the field, it typically cannot be performed until a prototype can be constructed from a fairly mature design. Unfortunately, a significant amount of time and money have already been expended at this stage of development, and any changes to the design (to address a reliability shortfall) are typically quite costly. The Reliability Design ProcessWhile manufacturers regularly tout the reliability of their designs, too often one will find that the same organizations do not perform the necessary activities to ensure the longevity of their products. A similar problem is also found in much of the literature on engineering design, in which the importance of durability and reliability is emphasized, yet the actual techniques used to design reliability into the system are not discussed in detail. As a result, engineers are often unsure of which activities to perform, or do not know how to utilize the results of a specific analysis or test.

The Reliability Design ProcessWhile manufacturers regularly tout the reliability of their designs, too often one will find that the same organizations do not perform the necessary activities to ensure the longevity of their products. A similar problem is also found in much of the literature on engineering design, in which the importance of durability and reliability is emphasized, yet the actual techniques used to design reliability into the system are not discussed in detail. As a result, engineers are often unsure of which activities to perform, or do not know how to utilize the results of a specific analysis or test.

Browse the complete RELease Book Series.

Additional RMQ Publications

If you’re ready to jump to the next level, the RMQSI Knowledge Center also provides in-depth Handbooks covering specific reliability topics (e.g., Handbook of Reliability Prediction Models, New Weibull Handbook), as well as comprehensive Toolkits, Databooks and Analysis Application Guides, including the popular System Reliability Toolkit and the Part Reliability Databooks.