| Data & Tools | Publications | Training |

What is it?

Weibull Analysis is a methodology for determining reliability characteristics and trends from field and/or test data. It allows decisions to be made based on a limited amount data. A special case with very few data points is WeiBayes Analysis. Results for a two-parameter Weibull Analysis provide estimates of an improving/degrading reliability trend (value of β) and the characteristic life (value of α, the estimated time at which 63.2% of a population will have failed due to a specific failure mode).

What’s the payoff?

It provides a better understanding of how parts and systems are performing compared to expectations so that design/process improvements can be planned and warranties can be cost-effectively defined and implemented.

How can we help?

- Perform Weibull, WeiBayes or Dauser shift analyses to characterize the reliability of your products

- Develop custom software tools to automate Weibull Analysis of the data in your databases

- Help define corrective actions for problems identified as the result of Weibull, WeiBayes and other forms of reliability analyses

- Develop corrective action tracking systems

- Help develop data collection processes and systems so that the right data is available for analysis and decision making

Related Data & Tools:

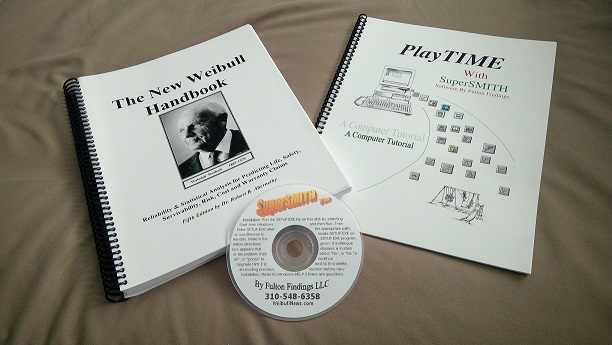

The SuperSmith® Package by Fulton Findings LLC

The SuperSmith® Package by Fulton Findings LLC

SuperSMITH®, developed by Fulton Findings LLC, is the leading software package for Weibull Engineering. The software comes on a single CD and installs on standard Windows® systems or Windows emulators in seconds. This software performs variability analysis for life data or for dimension data. Important uses are for reliability, safety, maintainability, supportability, quality control, product assurance, sizing, and warranty analysis.

Staff at the RMQSI Knowledge Center have provided many years of value-added consulting and software/tool development experience in the RMQ Engineering disciplines, to both commercial and government clients. Browse through our website to learn more and contact us to see how we can develop software and tools tailored to the specific RMQ needs of your organization.

Related Publications:

Practical Applications of the RIAC System Reliability ToolkitThe purpose of this publication is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities. It is intended to be used as a companion to the RIAC “System Reliability Toolkit”, as the foundations of all of the techniques illustrated in this publication are discussed therein.

Practical Applications of the RIAC System Reliability ToolkitThe purpose of this publication is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities. It is intended to be used as a companion to the RIAC “System Reliability Toolkit”, as the foundations of all of the techniques illustrated in this publication are discussed therein. The New Weibull Handbook, 5th Ed.Reliability & Statistical Analysis for Predicting Life, Safety, Risk, Support Costs, Failures, and Forecasting Warranty Claims, Substantiation and Accelerated Testing, Using Weibull, Log Normal, Crow-AMSAA, Probit and Kaplan-Meier Models.

The New Weibull Handbook, 5th Ed.Reliability & Statistical Analysis for Predicting Life, Safety, Risk, Support Costs, Failures, and Forecasting Warranty Claims, Substantiation and Accelerated Testing, Using Weibull, Log Normal, Crow-AMSAA, Probit and Kaplan-Meier Models. Weibull AnalysisThe statistical analysis of an item’s failure data is widely regarded as one of the most accurate techniques for assessing its reliability in a specific application or environment. Though there are many different statistical distributions (e.g., exponential, lognormal, etc.), the Weibull distribution is especially useful because of its ability to characterize a wide range of potential data trends.

Weibull AnalysisThe statistical analysis of an item’s failure data is widely regarded as one of the most accurate techniques for assessing its reliability in a specific application or environment. Though there are many different statistical distributions (e.g., exponential, lognormal, etc.), the Weibull distribution is especially useful because of its ability to characterize a wide range of potential data trends.

Lunchtime Learning SeriesThe “Lunchtime Learning” series is a group of short course tutorials are aimed at providing a basic introduction to a variety of topics in which our community members have expressed an interest.

Lunchtime Learning SeriesThe “Lunchtime Learning” series is a group of short course tutorials are aimed at providing a basic introduction to a variety of topics in which our community members have expressed an interest. Which Design is More Reliable? Weibull Provides Answers!Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More

Which Design is More Reliable? Weibull Provides Answers!Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More