| Reliability is defined as performance of a function over time, whether it applies to a commercial product or a military system. Commercial product reliability is usually driven by such factors as warranty cost goals, competitive marketing strategies, and liability concerns while the military wants to meet the operational needs of users while also meeting support cost objectives. These objectives usually lead to product or system requirements being specified by a mission reliabilitymetric and a logistics reliability metric. If the system or product doesn’t include redundancy, these metrics are equal. For simplicity, let’s limit the discussion to mean-time-between-critical-failures (MTBCF) as the mission reliability metric and mean-time-between-failure (MTBF) as the logistics reliability metric. | |

| Another distinction is the one between inherent reliability and operational reliability. Many studies have shown that there is a degradation from inherent reliability to operational (or field reliability) caused by factors that are usually considered beyond the control of designers. The studies usually show the level of degradation is dependent on such factors as the environmental conditions, the design complexity, and the equipment function. | |

Developing reliability quantitative goals or requirements usually involves the following (often iterative) steps:

|

|

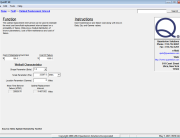

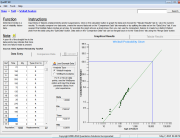

| It is the last step of this process that we’ve chosen to concentrate on using a couple of handy tools. The first is the “Reliability Potential” tool in the Quanterion Automated Reliability Toolkit (QuART)” desktop tool set (Demo versions of both Quart PRO and Quart ER are available for FREE download). This tool is a simplification of the MIL-HDBK-217 “Reliability Prediction of Electronic Equipment” methodology where all you need as input variables in order to to estimate the reliability are the expected operational environment, the approximate number of parts, and the general quality levels of the parts. The tool allows you to assume a “typical digital” or “typical analog” part type distribution, or allows you to enter a more precise distribution if you know it. Using this tool, you can quickly determine what levels of reliability can be achieved for variations of the input conditions. Of course, for the non-believer in MIL-HDBK-217, you can still use the tool. Just apply your favorite experience “K-factor” to the result. The following example demonstrates the tool’s use in checking to see if a signal processor with a potential logistics MTBF of 1000 hours in a ground mobile environment is realistic. | |

1. Open the “Reliability Potential” tool on the QuART “Conceptual” tab. |

|

2. Enter the approximate number of parts (600), the expected operating environment (Ground Mobile), and the expected quality levels of the parts (Commercial) employed in the design. |

|

| 3. Choose “digital” as more appropriate than “analog” because we don’t have better knowledge of the part type distribution. | |

| 4. Read the “MTBF” as 840 hours. | |

| 5. At this point, you can play “what if” analyses with all of the input variables until you can arrive at a conclusion as to whether the requirement is achievable. | |

| 6. Conclusion: In this case because, we know that the MIL-HDBK-217 “Commercial Level” part quality factors are considered by most people to be overly conservative (and therefore the 840 hours as conservative), we can accept the requirement as being appropriate. | |

| If the use of these tools indicates that the needed reliability levels are not realistic, it doesn’t mean that they can’t be required and achieved. It just means that extraordinary (and costly) efforts will probably be required to achieve them. | |

More News

- September 2025 Reliability Engineering Open Training

- New Electronic Derating Resource to Improve System Reliability

- Fall 2022 Reliability Engineering Training

- Quanterion Solutions Announces June 2022 Open Training

- New Reliability Engineering Book Bundle at 30% Off

- Quanterion Announces Winter 2021 Reliability Engineering Open Training

- Quanterion Solutions Hosts Reliability Fall 2021 Open Training Sessions

- Registration Available for Open Training – Winter 2020 Session!

- Registration Available for: Open Training – Fall 2020 Session!

- RMQSI & QSI Hosts Open Training – Fall 2018 Session!

Recent Reliability Ques

- Confidence Bounds on the Mean Time Between Failure (MTBF) for a Time-Truncated Test

- Maintenance Planning with Wearout Failure Modes

- Maintenance Planning with a Constant Failure Rate

- Maintenance Planning with Early Failures

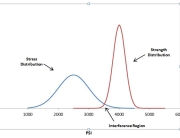

- Interference Stress/Strength Analysis

- Derating

- Models Commonly Used to Measure Reliability Growth

- How Good Is Your Reliability Approach?

- Solving the Complex RBD-Series Parallel System with a Keystone Component

- Environmental Stress Screening: Basic Steps in Choosing an ESS Profile