Reliability Problem Solving addresses the use of an appropriately tailored suite of reliability engineering activities, tools, methods, procedures, etc., to cost-effectively identify and correct design/process reliability problems.

Quanterion Solutions Hosts Reliability Fall 2021 Open Training Sessions

Fall 2021 Open Training is now closed for registrations. Discover Quanterion’s Winter 2021 Open Training.

Quanterion Solutions is offering reliability engineering open training this fall on Tuesday, Sept. 14 through Thursday, Sept. 16, 2021. The hands-on training will be hosted at the San Diego Training and Conference Center in San Diego, CA.

Attendees can choose between two course… Read More

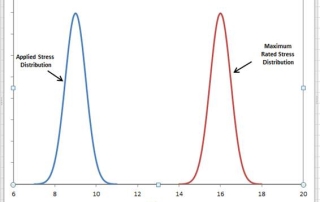

Derating

The practice of limiting electrical, thermal and mechanical stresses on parts to levels below their specified ratings is called derating. MIL-STD-721C offers the following definitions of derating:

Using an item in such a way that applied stresses are below rated values

The lowering of the rating of an item in one stress field to allow an increase… Read More