We publish electronic versions of “Reliability Ques” periodically as a means of keeping our community up-to-date on effective tools, techniques, and approaches to improving the reliability, maintainability, and quality of products and systems.

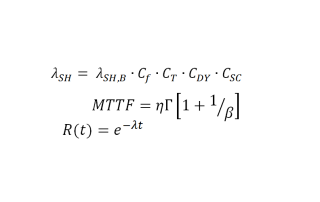

Understanding Your Product Through Reliability Modeling

How Much Reliability is Enough?

Reliability is defined as performance of a function over time, whether it applies to a commercial product or a military system. Commercial product reliability is usually driven by such factors as warranty cost goals, competitive marketing strategies, and liability concerns while the military wants to meet the operational needs of users while also meeting support… Read More

System Spares – What’s the “Right” Answer?

Using Accelerated Life Testing to Assess Warranty Risk

Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your Design

Which Design is More Reliable? Weibull Provides Answers!

Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More

How Complete is Your Reliability Tool Set?

Whether you’re developing consumer electronics in a competitive market or ground-based radars for the Government, there are lots of tools to have in your arsenal to help make your designs reliable and maintainable. Using a broad definition of tools, your arsenal should include design rules and procedures, analysis methodologies, test approaches and strategies, and field… Read More

Is Asset Management For You?

What is Asset Management?

Asset Management is being called by many the “final frontier” of achieving major gains in operating effectiveness, corporate profitability and shareholder value. It has been reported that North American industry could recover $200M to $500M annually through improved physical Asset Management. To demonstrate the critical nature of managing assets the Department of… Read More