| Data & Tools | Publications | Training |

What is it?

A Parts/Materials Selection and Application Program is an approach to controlling those items that are used in your product/system design. It establishes the requirements and defines the controls that make them acceptable for use for a given design, application environment and expected life. It considers related issues such as the risks associated with new technologies, part/material obsolescence and Diminishing Manufacturing Sources (DMS).

What’s the payoff?

The reliability of parts/materials varies widely. The choice of which to use has significant implications for product/system reliability and, as a result, total life cycle cost. Proper attention to parts/materials control can minimize the proliferation of different items within a company, or even on the same program by different engineers, thereby reducing the cost of inventory and limiting the number of specification control drawings to support a product/system.

How can we help?

- Define and implement parts/materials selection, application and control programs within your organization

- Develop preferred parts/materials lists for your organization, including on-line databases to facilitate their use

- Perform research and provide alternatives for solving parts/materials problems

- Perform independent reviews to assess the suitability of selected parts/materials for your specific applications

- Develop requirements documents for controlling suppliers

- Define and/or set up systems for monitoring supplier performance

- Audit suppliers’ manufacturing and quality processes/procedures

Related Data & Tools:

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center).

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center). QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

Related Publications:

Techniques to Evaluate Long-Term Aging of Systems (LAST)The objective of this report is to highlight the impact of long-term aging effects on parts, assemblies and equipments by investigating characteristics of aging as they impact specific material classes.

Techniques to Evaluate Long-Term Aging of Systems (LAST)The objective of this report is to highlight the impact of long-term aging effects on parts, assemblies and equipments by investigating characteristics of aging as they impact specific material classes.

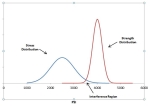

Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More

Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your DesignEngineers are often faced with the problem of optimizing a process that includes a number of input variables. It could be an analysis of a manufacturing process, or even an analysis of a business process. They’re often challenged to find ways to reduce

Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your DesignEngineers are often faced with the problem of optimizing a process that includes a number of input variables. It could be an analysis of a manufacturing process, or even an analysis of a business process. They’re often challenged to find ways to reduce Which Design is More Reliable? Weibull Provides Answers!Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More

Which Design is More Reliable? Weibull Provides Answers!Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life item that had a specified 5% minimum… Read More

Related Training:

Staff at the RMQSI Knowledge Center have provided many years of value-added consulting and training experience in the RMQ Engineering disciplines, to both commercial and government clients. Browse through our website to learn more and contact us to see how we can develop and present customized training to your organization.