| Data & Tools | Publications | Training |

What is it?

Reliability Problem Solving addresses the use of an appropriately tailored suite of reliability engineering activities, tools, methods, procedures, etc., to cost-effectively identify and correct design/process reliability problems.

What’s the payoff?

Reliability problem solving activities actively promote reliability growth by identifying and eliminating/mitigating failure modes/ mechanisms in designs and processes. Successfully minimizing the effects of failure can result in lower risk in meeting reliability requirements, an increase in new/repeat business and reduced warranty and maintenance costs.

How can we help?

- Ensure that your reliability data is effectively collected, analyzed and used for informed decision making: Failure Reporting, Analysis and corrective Action System (FRACAS)

- Perform analyses of your designs/processes and make recommendations to help you better understand the causes of failure: Failure Modes, Effects and Criticality Analysis (FMECA), Fault Tree Analysis (FTA), Worst Case Analysis (WCA), Physics-of-Failure (PoF) Analysis

- Perform analyses of your test programs and make recommendations to ensure a cost-effective, value-added reliability test strategy: Design of Experiments (DOE), Accelerated Life Test (ALT), Reliability Growth Test (RGT), Reliability Screening

Related Data & Tools:

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center).

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center). QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

Related Publications:

System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community.

System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community. Achieving System Reliability Growth Through Robust Design and TestThis book offers new definitions of how failures can be characterized, and how those new definitions can be used to develop metrics that will quantify how effective a Design for Reliability (DFR) process is in (1) identifying failure modes and (2) mitigating their root failure causes.

Achieving System Reliability Growth Through Robust Design and TestThis book offers new definitions of how failures can be characterized, and how those new definitions can be used to develop metrics that will quantify how effective a Design for Reliability (DFR) process is in (1) identifying failure modes and (2) mitigating their root failure causes.

- Quanterion Solutions Hosts Reliability Fall 2021 Open Training SessionsFall 2021 Open Training is now closed for registrations. Discover Quanterion’s Winter 2021 Open Training. Quanterion Solutions is offering reliability engineering open training this fall on Tuesday, Sept. 14 through Thursday, Sept. 16, 2021. The hands-on training will be hosted at the San Diego Training and Conference Center in San Diego, CA. Attendees can choose between… Read More

DeratingThe practice of limiting electrical, thermal and mechanical stresses on parts to levels below their specified ratings is called derating. MIL-STD-721C offers the following definitions of derating: Using an item in such a way that applied stresses are below rated values The lowering of the rating of an item in one stress field to allow… Read More

DeratingThe practice of limiting electrical, thermal and mechanical stresses on parts to levels below their specified ratings is called derating. MIL-STD-721C offers the following definitions of derating: Using an item in such a way that applied stresses are below rated values The lowering of the rating of an item in one stress field to allow… Read More Mission Reliability and Logistics Reliability: A Design ParadoxThe goal of improving system reliability often presents a design paradox; “mission” reliability cannot be increased without simultaneously decreasing “logistics” reliability. When faced with the challenge of a system that has inadequate reliability to meet specification requirements, hardware redundancy is often implemented, leading to

Mission Reliability and Logistics Reliability: A Design ParadoxThe goal of improving system reliability often presents a design paradox; “mission” reliability cannot be increased without simultaneously decreasing “logistics” reliability. When faced with the challenge of a system that has inadequate reliability to meet specification requirements, hardware redundancy is often implemented, leading to Using Accelerated Life Testing to Assess Warranty RiskDuring a recent project, a question arose about the feasibility of providing a ten year warranty for a new system. The system consisted of a proven electronic assembly and 40 newly designed hybrid electronic modules. Warranty costs could be significant if reliability risks were not fully understood. The company producing the system

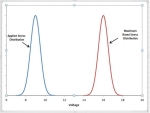

Using Accelerated Life Testing to Assess Warranty RiskDuring a recent project, a question arose about the feasibility of providing a ten year warranty for a new system. The system consisted of a proven electronic assembly and 40 newly designed hybrid electronic modules. Warranty costs could be significant if reliability risks were not fully understood. The company producing the system

Related Training:

Fall 2022 Open Training: Quantitative Reliability Analyses – Practical Approaches

This course is closed for registrations. Email Qinfo@Quanterion.com for other openings.

The purpose of this course is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities.

Course Dates

Tuesday, Nov. 15 – Thursday, Nov. 17, 2022.

Course Location

DoubleTree Suites by Hilton Orlando – Disney Springs

2305 Hotel Plaza Blvd.

Lake Buena Vista, FL 32830

Register By

Oct. 14, 2022.

Registering a group? Call us at (315) 732-0097 to discuss the best rate for you.

The registration fee includes a copy of Quanterion Solutions’ popular “System Reliability Toolkit-V” and “QuART PRO” software (a $264 total value).

View the other course option in Fall 2022 Open Training, Software Failure Modes Effects Analysis, offered the same date and time.

Fall 2022 Open Training: Quantitative Reliability Analyses – Practical Approaches

This course is closed for registrations. Email Qinfo@Quanterion.com for other openings.

The purpose of this course is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities.

Course Dates

Tuesday, Nov. 15 – Thursday, Nov. 17, 2022.

Course Location

DoubleTree Suites by Hilton Orlando – Disney Springs

2305 Hotel Plaza Blvd.

Lake Buena Vista, FL 32830

Register By

Oct. 14, 2022.

Registering a group? Call us at (315) 732-0097 to discuss the best rate for you.

The registration fee includes a copy of Quanterion Solutions’ popular “System Reliability Toolkit-V” and “QuART PRO” software (a $264 total value).

View the other course option in Fall 2022 Open Training, Software Failure Modes Effects Analysis, offered the same date and time.