| Data & Tools | Publications | Training |

What is it?

Military and industrial products and systems may be required to operate or function significantly longer than what they were originally designed for (years, miles, cycles, etc.). Lifetime Extension Assessment addresses the potential risks and possible solutions associated with extending the lives of products, systems and processes.

What’s the payoff?

Informed decisions to extend the original useful life of a design or process must address important material, part and process limitations and the potential solutions that are available to minimize technical and financial risk. The primary payoff is in the significant cost avoidance associated with the success of a Lifetime Extension Assessment study when compared to the cost of designing and developing an entirely new product, system or process.

How can we help?

- Assess the risks associated with extending the life (storage and/or operation) of your product, system or process

- Identify design/process changes and periodic testing/inspections that are appropriate to minimizing the risks associated with an extension decision

- Address technology obsolescence issues and the availability of maintenance capability associated with the extension

- Improve maintenance procedures and tools, and provide training, to compensate for the loss of experienced personnel

- Address cost implications associated with life extension alternatives

Related Data & Tools:

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center).

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center). QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

Related Publications:

Reliability Toolkit: Commercial Practices EditionThe “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit owners to date.

Reliability Toolkit: Commercial Practices EditionThe “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit owners to date. System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community.

System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community. Techniques to Evaluate Long-Term Aging of Systems (LAST)The objective of this report is to highlight the impact of long-term aging effects on parts, assemblies and equipments by investigating characteristics of aging as they impact specific material classes.

Techniques to Evaluate Long-Term Aging of Systems (LAST)The objective of this report is to highlight the impact of long-term aging effects on parts, assemblies and equipments by investigating characteristics of aging as they impact specific material classes.

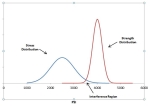

Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More

Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts?

System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts?