| Data & Tools | Publications | Training |

What is it?

Asset Management is any system that monitors/ maintains things of value to an entity or group, and can cover tangible assets or intangible concepts (intellectual property; goodwill). Enterprise Asset Management (EAM) is an optimized systematic process of cost-effectively designing, constructing, commissioning, operating, maintaining and decommissioning/replacement of plant, equipment and/or facilities. Reliability Centered Maintenance is the foundation of EAM.

What’s the payoff?

EAM allows an organization to reduce costs (maintenance, production and labor), increase maintenance productivity, and minimize the number of equipment breakdowns and the associated downtime.

How can we help?

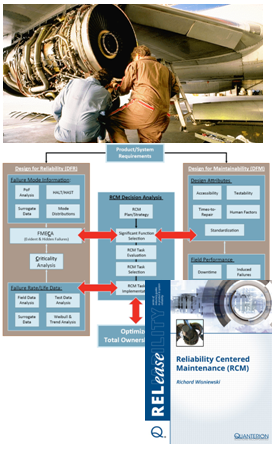

- Define a Reliability Program that integrates Design for Reliability (DFR) and Maintainability (DFM) concepts into an optimized asset management strategy

- Perform analyses to identify critical assets representing the largest payback to the EAM strategy

- Collect and analyze data/information to track asset performance and improve/expand the EAM strategy

- Develop or improve an organization’s data collection analysis capabilities, including web-based tools and databases

- Provide training in all aspects of EAM related to DFR, DFM, RCM, Optimized Total Ownership Cost and Affordability

Related Data & Tools:

Staff at the RMQSI Knowledge Center have provided many years of value-added consulting and software/tool development experience in the RMQ Engineering disciplines, to both commercial and government clients. Browse through our website to learn more and contact us to see how we can develop software and tools tailored to the specific RMQ needs of your organization.

Related Publications:

Reliability Toolkit: Commercial Practices EditionThe “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit owners to date.

Reliability Toolkit: Commercial Practices EditionThe “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit owners to date. System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community.

System Reliability Toolkit-VThe System Reliability Toolkit provides technical guidance in all aspects of system reliability, addressing both software reliability and human factors to better reflect the changing requirements of defense community. The Influence of Reliability, Maintainability, Quality, Supportability and Interoperability on System AffordabilityThe relationship of R&M costs to the Sustainment and Availability Key Performance Parameters (KPPs), the Reliability and Ownership Cost Key System Attributes (KSAs) and the RAM-C Manual processes are discussed. The publication comes with a MS Excel-based tool titled "Optimized Reliability Requirements and Cost Analysis" (OR2CA), developed by Quanterion Solutions Incorporated, that automates the RAM-C process and incorporates three innovative ideas from the Authors presented in the publication.

The Influence of Reliability, Maintainability, Quality, Supportability and Interoperability on System AffordabilityThe relationship of R&M costs to the Sustainment and Availability Key Performance Parameters (KPPs), the Reliability and Ownership Cost Key System Attributes (KSAs) and the RAM-C Manual processes are discussed. The publication comes with a MS Excel-based tool titled "Optimized Reliability Requirements and Cost Analysis" (OR2CA), developed by Quanterion Solutions Incorporated, that automates the RAM-C process and incorporates three innovative ideas from the Authors presented in the publication. Reliability Centered Maintenance (RCM)The RCM process was first envisioned in the 1960s when it was discovered that the standard process of overhauling aircraft after a given number of flight hours led to little or no improvement in system reliability or safety. To address these issues, the FAA, in partnership with the aviation industry, created a working group of Subject Matter Experts to study the Preventive Maintenance process and make recommendations for improvements to maintenance practices and planning. Since that time, the RCM process has continued to evolve into the numerous RCM methods that are available today.

Reliability Centered Maintenance (RCM)The RCM process was first envisioned in the 1960s when it was discovered that the standard process of overhauling aircraft after a given number of flight hours led to little or no improvement in system reliability or safety. To address these issues, the FAA, in partnership with the aviation industry, created a working group of Subject Matter Experts to study the Preventive Maintenance process and make recommendations for improvements to maintenance practices and planning. Since that time, the RCM process has continued to evolve into the numerous RCM methods that are available today.

- Introduction to Reliability Centered Maintenance (1 Day)Course Description This 1-day course provides a general introduction to Reliability-Centered Maintenance (RCM), explaining the basic terminology, analyses, and overall purpose and goal of performing RCM. In addition to providing a brief history on the various maintenance approaches employed by different industries, the course identifies practical RCM applications, outlining the steps involved with planning, implementing… Read More

Reliability: Costly, or Cost Effective?There are those who would argue that the costs of reliability activities associated with developing new products have little payoff. Whether we’re talking about commercial products or military systems, we don’t agree. Concepts like Life Cycle Costs, Total Ownership Costs, Reliability-based Maintenance, Performance-Based Logistics, and others clearly recognize the contribution of reliability activities in reducing… Read More

Reliability: Costly, or Cost Effective?There are those who would argue that the costs of reliability activities associated with developing new products have little payoff. Whether we’re talking about commercial products or military systems, we don’t agree. Concepts like Life Cycle Costs, Total Ownership Costs, Reliability-based Maintenance, Performance-Based Logistics, and others clearly recognize the contribution of reliability activities in reducing… Read More System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts?

System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts? Is Asset Management For You?What is Asset Management? Asset Management is being called by many the “final frontier” of achieving major gains in operating effectiveness, corporate profitability and shareholder value. It has been reported that North American industry could recover $200M to $500M annually through improved physical Asset Management. To demonstrate the critical nature of managing assets the Department… Read More

Is Asset Management For You?What is Asset Management? Asset Management is being called by many the “final frontier” of achieving major gains in operating effectiveness, corporate profitability and shareholder value. It has been reported that North American industry could recover $200M to $500M annually through improved physical Asset Management. To demonstrate the critical nature of managing assets the Department… Read More

Related Training:

Reliability Centered MaintenanceThis module provides a detailed guide on the steps involved in most RCM programs. The course steps the user through the classical RCM process beginning from RCM preparation to sustainment activities.

Reliability Centered MaintenanceThis module provides a detailed guide on the steps involved in most RCM programs. The course steps the user through the classical RCM process beginning from RCM preparation to sustainment activities.