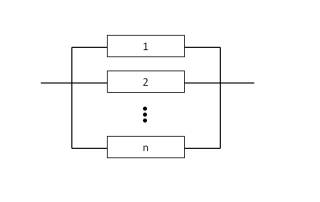

Understanding Your Product Through Reliability Modeling

A reliability model represents a clear picture of your product’s functional interdependencies providing a means to trade-off design alternatives and to identify areas for design improvement. The models are also helpful in:

Identifying of critical items and single points of failure

Allocating reliability goals to portions of the design

Providing a framework for comparing estimated reliability to product… Read More