| Data & Tools | Publications | Training |

What is it?

A reliability model mathematically defines the interdependencies between hardware/ software/human elements and their combined contributions to failure. A prediction calculates failure rates using that model so that a reliability metric can be quantified to assess design tradeoffs, and as an estimate of operational reliability after a product is delivered.

What’s the payoff?

The modeling/prediction/assessment process facilitates greater understanding of the impact of failure mechanisms and modes on critical design performance parameters, allowing an organization to cost-effectively modify the design and efficiently allocate resources to mitigate their impact.

How can we help?

- Develop a reliability model/prediction of your designs using your data, or commercial failure rate and life methodologies (217PlusTM, MIL-HDBK-217, Telcordia, Nonelectronic Part Reliability Data (NPRD), Physics-of-Failure, etc.)

- Use the results to identify specific areas of reliability risk and recommend approaches to eliminate or reduce them

- Use models and simulation techniques to perform (or help you perform) tradeoffs to compare results for different design alternatives

- Tailor reliability modeling, simulation and prediction tools for your company’s internal use

- Perform an objective review of reliability models/predictions performed by others

- Develop specialized reliability-based tools/databases

Related Data & Tools:

Quanterion Automated Databook (NPRD-2016, FMD-2016, EPRD-2014)This interactive software tool provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hard copy products. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels. A User's Guide is provided to assist the user in understanding the software capabilities.

*NOTE: Please contact Quanterion at (877) 808-0097 (Toll Free), or (315) 732-0097 if you are a 3rd party software tool developer and would like to inquire about incorporating this data into your product.

*Available in Download, CD-ROM, and Subscriptions.

*NOTE: The Automated Databook version is not a PDF version of the hardcopy document. The CD-ROM and download versions are Windows compatible database software tools that operate in the Windows environment. The subscription version runs in a web browser and will work on any operating system including Apple MacOS and Linux machines.

This product is also offered as a subscription. Click here to view subscription options.

Quanterion Automated Databook (NPRD-2016, FMD-2016, EPRD-2014)This interactive software tool provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hard copy products. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels. A User's Guide is provided to assist the user in understanding the software capabilities.

*NOTE: Please contact Quanterion at (877) 808-0097 (Toll Free), or (315) 732-0097 if you are a 3rd party software tool developer and would like to inquire about incorporating this data into your product.

*Available in Download, CD-ROM, and Subscriptions.

*NOTE: The Automated Databook version is not a PDF version of the hardcopy document. The CD-ROM and download versions are Windows compatible database software tools that operate in the Windows environment. The subscription version runs in a web browser and will work on any operating system including Apple MacOS and Linux machines.

This product is also offered as a subscription. Click here to view subscription options. Failure Mode / Mechanism Distributions – FMD-2016The 2016 Edition of the Failure Mode/Mechanisms Distribution (FMD-2016) contains field failure mode and mechanism distribution data on a variety of electrical, mechanical, and electromechanical parts and assemblies. This data can be used to apportion an item’s failure rate into modal elements and assist in the performance of reliability analyses and assessments such as Failure Modes, Effects and Criticality Analysis (FMECA) and Fault Tree Analysis (FTA). FMD-2016 contains over 990,000 new records, a 10 fold increase over the 98,000 records presented in its predecessor, FMD-2013.

Failure Mode / Mechanism Distributions – FMD-2016The 2016 Edition of the Failure Mode/Mechanisms Distribution (FMD-2016) contains field failure mode and mechanism distribution data on a variety of electrical, mechanical, and electromechanical parts and assemblies. This data can be used to apportion an item’s failure rate into modal elements and assist in the performance of reliability analyses and assessments such as Failure Modes, Effects and Criticality Analysis (FMECA) and Fault Tree Analysis (FTA). FMD-2016 contains over 990,000 new records, a 10 fold increase over the 98,000 records presented in its predecessor, FMD-2013.

Free Podcast Available! Watch Now!

View Introduction View Part DescriptorsThis product is also offered as a subscription. Click here to view subscription options.*NOTE: The Automated Databook version is not a PDF version of the hardcopy document. The CD-ROM and download versions are Windows compatible database software tools that operate in the Windows environment. The subscription version runs in a web browser and will work on any operating system including Apple MacOS and Linux machines.Contact us at qinfo@quanterion.com for quantities of over 10.

Quanterion Automated Databook (NPRD-2016, FMD-2013, EPRD-2014)This interactive software tool provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hard copy products. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels.

Quanterion Automated Databook (NPRD-2016, FMD-2013, EPRD-2014)This interactive software tool provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hard copy products. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels. Reliability Online Automated Databook System (ROADS) – All Databooks (NPRD EPRD FMD) SubscriptionThis interactive online tool is a subscription service that provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hardcopy databooks. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels.

Reliability Online Automated Databook System (ROADS) – All Databooks (NPRD EPRD FMD) SubscriptionThis interactive online tool is a subscription service that provides efficient search and retrieval of all information contained in the EPRD, NPRD, and FMD hardcopy databooks. Containing a built-in search engine, information may be searched on part number, part types, manufacturer, and National Stock Number (NSN). Additional filters are available to specify application environment and quality levels. Nonelectronic Parts Reliability Data – NPRD-2016Nonelectronic Parts Reliability Data (NPRD) provides failure rate data for a wide variety of component types including mechanical, electromechanical, and electronic assemblies. It provides summary and detailed data sorted by part type, quality level, environment and data source.

Nonelectronic Parts Reliability Data – NPRD-2016Nonelectronic Parts Reliability Data (NPRD) provides failure rate data for a wide variety of component types including mechanical, electromechanical, and electronic assemblies. It provides summary and detailed data sorted by part type, quality level, environment and data source. 217Plus™ Bill of Materials Import SpreadsheetQuanterion has also developed the 217Plus_BOM_Tool-Rev2.xls spreadsheet, designed to facilitate data imports into the RIAC's 217Plus™ software. This Excel®-based workbook was developed by Quanterion Solutions for use with the 217Plus™ Application Notes 1 through 4. Together, they can facilitate Importing BOM and Component data to the 217Plus™ Software in a consistent and error free manner.

217Plus™ Bill of Materials Import SpreadsheetQuanterion has also developed the 217Plus_BOM_Tool-Rev2.xls spreadsheet, designed to facilitate data imports into the RIAC's 217Plus™ software. This Excel®-based workbook was developed by Quanterion Solutions for use with the 217Plus™ Application Notes 1 through 4. Together, they can facilitate Importing BOM and Component data to the 217Plus™ Software in a consistent and error free manner. Failure Mode / Mechanism Distributions – FMD-2013FMD-2013 is the third release in a series of Reliability Information Analysis Center (RIAC) databooks that contain Failure Mode and Mechanism Distribution data. It updates the 1997 Edition of the databook, providing an expanded compendium of failure mode/mechanism data for electronic, electromechanical and mechanical parts, components and assemblies.

Failure Mode / Mechanism Distributions – FMD-2013FMD-2013 is the third release in a series of Reliability Information Analysis Center (RIAC) databooks that contain Failure Mode and Mechanism Distribution data. It updates the 1997 Edition of the databook, providing an expanded compendium of failure mode/mechanism data for electronic, electromechanical and mechanical parts, components and assemblies. Electronic Parts Reliability Data – EPRD-2014This document contains reliability data on both commercial and military electronic components for use in reliability analyses. It contains failure rate data on integrated circuits, discrete semiconductors (diodes, transistors, optoelectronic devices), resistors, capacitors, and inductors/transformers, all of which were obtained from the field usage of electronic components.

Electronic Parts Reliability Data – EPRD-2014This document contains reliability data on both commercial and military electronic components for use in reliability analyses. It contains failure rate data on integrated circuits, discrete semiconductors (diodes, transistors, optoelectronic devices), resistors, capacitors, and inductors/transformers, all of which were obtained from the field usage of electronic components. QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center).

QuART PROThe QuART software series represents the fourth generation of the highly popular "Reliability Toolkit" series of RMQ engineering aids originated in 1988 by Quanterion personnel while working at the Rome Laboratory (formerly Rome Air Development Center). QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

QuART ER (Enhancing Reliability)This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the "Ask a Quanterion Expert" function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion. Stress-Derating Spreadsheet Calculator – (SD-18 Derating Standard)Excel-based software tool that implements the derating guidelines stated in NAVSEA SD-18, Notice 3.

Stress-Derating Spreadsheet Calculator – (SD-18 Derating Standard)Excel-based software tool that implements the derating guidelines stated in NAVSEA SD-18, Notice 3.

Related Publications:

Practical Applications of the RIAC System Reliability ToolkitThe purpose of this publication is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities. It is intended to be used as a companion to the RIAC “System Reliability Toolkit”, as the foundations of all of the techniques illustrated in this publication are discussed therein.

Practical Applications of the RIAC System Reliability ToolkitThe purpose of this publication is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities. It is intended to be used as a companion to the RIAC “System Reliability Toolkit”, as the foundations of all of the techniques illustrated in this publication are discussed therein. HDBK-217Plus™: 2015 (Pre-Notice 1)Quanterion Solutions developed this update to the popular 217PlusTM ‘Handbook of Reliability Prediction Models’ to replace the 2006 edition developed for the Reliability Information Analysis Center (RIAC). Available exclusively through Quanterion, 217Plus™:2015 contains new failure rate models covering Photonics components and updates to the twelve original 217Plus™ component failure rate models based on new data.

HDBK-217Plus™: 2015 (Pre-Notice 1)Quanterion Solutions developed this update to the popular 217PlusTM ‘Handbook of Reliability Prediction Models’ to replace the 2006 edition developed for the Reliability Information Analysis Center (RIAC). Available exclusively through Quanterion, 217Plus™:2015 contains new failure rate models covering Photonics components and updates to the twelve original 217Plus™ component failure rate models based on new data. Reliability Modeling – The RIAC Guide to Reliability Prediction, Assessment and EstimationThe intent of this book is to provide guidance on modeling techniques that can be used to quantify the reliability of a product or system. In this context, reliability modeling is the process of constructing a mathematical model that is used to estimate the reliability characteristics of a product.

Reliability Modeling – The RIAC Guide to Reliability Prediction, Assessment and EstimationThe intent of this book is to provide guidance on modeling techniques that can be used to quantify the reliability of a product or system. In this context, reliability modeling is the process of constructing a mathematical model that is used to estimate the reliability characteristics of a product. Reliability PredictionTraditionally, reliability predictions have been predominantly based on the results of a formal test program. While testing is a more than acceptable means of estimating a system’s performance in the field, it typically cannot be performed until a prototype can be constructed from a fairly mature design. Unfortunately, a significant amount of time and money have already been expended at this stage of development, and any changes to the design (to address a reliability shortfall) are typically quite costly.

Reliability PredictionTraditionally, reliability predictions have been predominantly based on the results of a formal test program. While testing is a more than acceptable means of estimating a system’s performance in the field, it typically cannot be performed until a prototype can be constructed from a fairly mature design. Unfortunately, a significant amount of time and money have already been expended at this stage of development, and any changes to the design (to address a reliability shortfall) are typically quite costly. Reliability ModelingWhile the benefits of the design for reliability (DFR) process are well understood in the engineering community, the application of these techniques becomes quite difficult as modern systems continue to evolve into increasingly complex designs. One of the most effective means of overcoming these challenges is the use of system modeling techniques.

Reliability ModelingWhile the benefits of the design for reliability (DFR) process are well understood in the engineering community, the application of these techniques becomes quite difficult as modern systems continue to evolve into increasingly complex designs. One of the most effective means of overcoming these challenges is the use of system modeling techniques. Physics-of-Failure ModelingThe traditional approach to product reliability has largely been based on the statistical analysis of an item’s failure data. Analysts would predict the probability of a part/system failure from the percentage of times that an item failed either during testing or from historical use in the field. Eventually, statistical distributions were fit to an item’s time-to-failure data, allowing for the estimation of more informative reliability characteristics (e.g., characteristic life, rate of failure, etc.).

Physics-of-Failure ModelingThe traditional approach to product reliability has largely been based on the statistical analysis of an item’s failure data. Analysts would predict the probability of a part/system failure from the percentage of times that an item failed either during testing or from historical use in the field. Eventually, statistical distributions were fit to an item’s time-to-failure data, allowing for the estimation of more informative reliability characteristics (e.g., characteristic life, rate of failure, etc.).

- Quanterion Solutions Hosts Reliability Fall 2021 Open Training SessionsFall 2021 Open Training is now closed for registrations. Discover Quanterion’s Winter 2021 Open Training. Quanterion Solutions is offering reliability engineering open training this fall on Tuesday, Sept. 14 through Thursday, Sept. 16, 2021. The hands-on training will be hosted at the San Diego Training and Conference Center in San Diego, CA. Attendees can choose between… Read More

Lunchtime Learning SeriesThe “Lunchtime Learning” series is a group of short course tutorials are aimed at providing a basic introduction to a variety of topics in which our community members have expressed an interest.

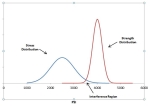

Lunchtime Learning SeriesThe “Lunchtime Learning” series is a group of short course tutorials are aimed at providing a basic introduction to a variety of topics in which our community members have expressed an interest. Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More

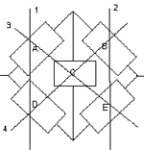

Interference Stress/Strength AnalysisIn simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure”. Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms of strength… Read More Solving the Complex RBD-Series Parallel System with a Keystone ComponentThe general form of this type of reliability block diagram has two series circuits in a parallel arrangement combined through a center or “keystone” unit. You are often given the reliability of each block and asked to calculate the reliability of the circuit. For example let’s say we are given the following five block arrangement… Read More

Solving the Complex RBD-Series Parallel System with a Keystone ComponentThe general form of this type of reliability block diagram has two series circuits in a parallel arrangement combined through a center or “keystone” unit. You are often given the reliability of each block and asked to calculate the reliability of the circuit. For example let’s say we are given the following five block arrangement… Read More Mission Reliability and Logistics Reliability: A Design ParadoxThe goal of improving system reliability often presents a design paradox; “mission” reliability cannot be increased without simultaneously decreasing “logistics” reliability. When faced with the challenge of a system that has inadequate reliability to meet specification requirements, hardware redundancy is often implemented, leading to

Mission Reliability and Logistics Reliability: A Design ParadoxThe goal of improving system reliability often presents a design paradox; “mission” reliability cannot be increased without simultaneously decreasing “logistics” reliability. When faced with the challenge of a system that has inadequate reliability to meet specification requirements, hardware redundancy is often implemented, leading to Better Reliability Predictions Using Experience DataThere are many approaches that can be used to predict the reliability of an item. Sometimes when asked to provide a “quick estimate” of an item’s reliability, the use of field experience is overlooked, or if no failures have occurred, overly conservative estimates are made by assuming one failure. This article describes a simple approach… Read More

Better Reliability Predictions Using Experience DataThere are many approaches that can be used to predict the reliability of an item. Sometimes when asked to provide a “quick estimate” of an item’s reliability, the use of field experience is overlooked, or if no failures have occurred, overly conservative estimates are made by assuming one failure. This article describes a simple approach… Read More Understanding Your Product Through Reliability ModelingA reliability model represents a clear picture of your product’s functional interdependencies providing a means to trade-off design alternatives and to identify areas for design improvement. The models are also helpful in:

Understanding Your Product Through Reliability ModelingA reliability model represents a clear picture of your product’s functional interdependencies providing a means to trade-off design alternatives and to identify areas for design improvement. The models are also helpful in: System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts?

System Spares – What’s the “Right” Answer?Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts? Making Sense Out of the Reliability Prediction BusinessReliability Predictions are commonly used in the development of products and systems to compare alternative design approaches and to assess progress toward reliability design goals. They’re often criticized as not being accurate forecasts of field reliability performance because they don’t usually account for all the factors

Making Sense Out of the Reliability Prediction BusinessReliability Predictions are commonly used in the development of products and systems to compare alternative design approaches and to assess progress toward reliability design goals. They’re often criticized as not being accurate forecasts of field reliability performance because they don’t usually account for all the factors